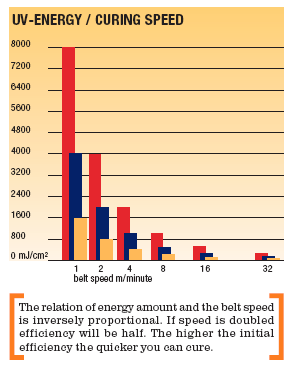

UV-ENERGY/CURING SPEED

UV-curing Screen Printing Inks

In numbers:

Highly reactive inks for paper and common

plastics such as PVC, PS or PP

(pre-treated) require between 100 and

350 mJ/cm2 (Coates MLS, UVE, UVPO,

UVN).

Inks for PMMA, PC or coated surfaces

with higher resistances, e.g. for technical

applications, require between 350 and

1.000 mJ/cm2 (UVP).

For decoration of metals or glass, inks

with quite a high energy requirement are

processed. Depending on applications

energy requirement is between 1.000

and 3.000 mJ/cm2 (UVK, UVGL).

ENERGY REQUIREMENT OF UV-INK TYPES

Ink A > Paper / PVC / PC: 100- 200 mJ/cm2

Ink B > PVC / PS / PP: 200- 350 mJ/cm2

Ink C > PC / PMMA: 350- 500 mJ/cm2

Ink D > coated metals: 500-1000 mJ/cm2

Ink E > metals, glass: 1000-3000 mJ/cm2

Back to top

|

|

UV

Tech Articles

UV-ENERGY/CURING SPEED

UV or Not UV in ScreenPrinting Inks

|